What are the symptoms of occupational disease?

Workers in many industries face different harmful occupational diseases on a daily basis. One of them is Hand Arm Vibration Syndrome (HAVS), which is a common occupational disease in various industries.

Hand Arm Vibration is vibration transmitted from work processes into workers’ hands and arms, and it mainly affects people who regularly use vibrating hand tools as well as workers in colder climates.

In many cases, workers are not even aware that holding materials being processed by machines can cause serious issues in the long term. Studies show that regular and frequent exposure to HAV can lead to permanent health effects. It’s safe to say that injuries caused by vibrations in the workplace could be prevented with further knowledge of HAVS.

Health conditions caused by vibration progress slowly. In the beginning, it starts with pain and tingling or numbness in the finger(s). Nerves are affected initially too, leading to changes in sensation. This can then be followed by Raynaud’s phenomenon, sometimes called Raynaud’s syndrome or disease.

With continued HAV exposure, the pain may develop into an injury or disease. Single “white” or blanched fingertip will occur, usually in conjunction with exposure to cold temperatures.

HAVS can take six months to six years to develop and as HAV exposure continues, especially in cold conditions, attacks increase in number, intensity, pain and duration. In the latter stages of HAVS, attacks occur in all seasons both on and off the job and they interfere in the work and non-work lives of afflicted individuals. In extreme and rare cases, the loss of blood supply to the fingers can lead to gangrene, which can require amputation.

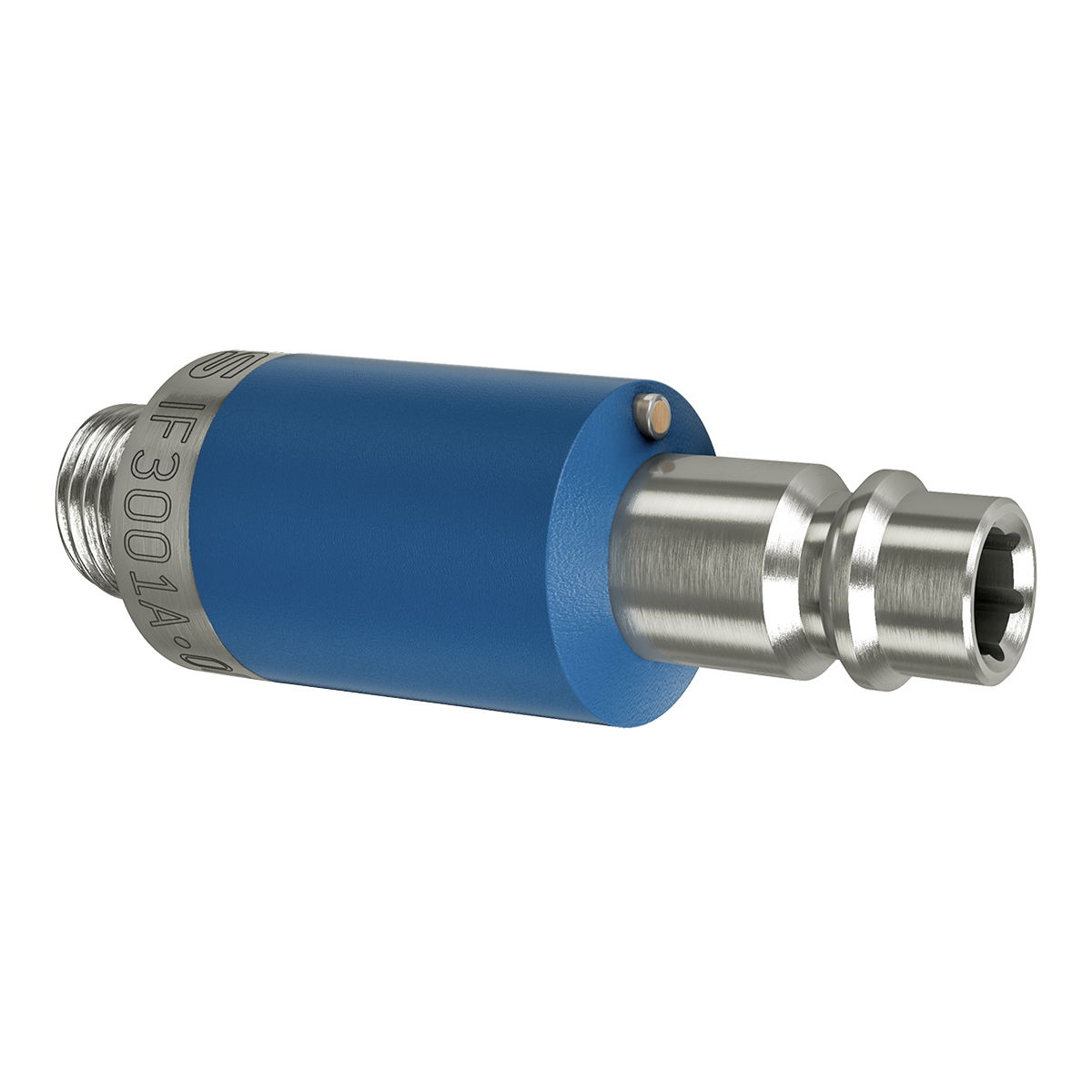

Sensors play an important role in the prevention of Hand Arm Vibration Syndrome. They have the ability to measure vibrations in hands and arms in three directions and read real-time trigger time. The data is transmitted automatically and wirelessly, and every worker or a supervisor will receive immediate notification when critical vibration limits have been reached. They can then take preventive steps to avoid harm to the hands by wearing softening gloves or changing the characteristics of work.

About Nordic Automation Systems

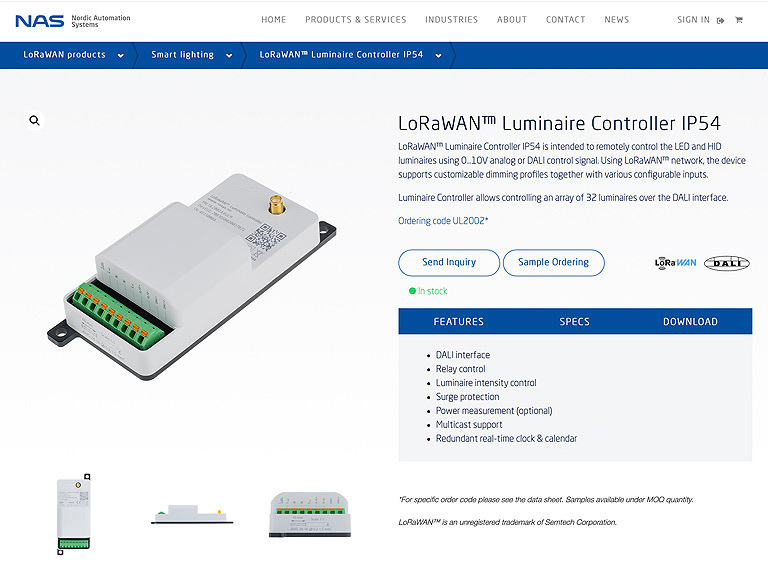

Nordic Automation Systems (NAS) is an industrial automation company, creating sensor technologies, data analysis and monitoring solutions.

NAS is one of the world’s leading provider of full vertical LoRaWAN solutions: sensors, gateways and Cloud – plug & play. LoRa technology enables them to provide end-to-end LoRaWAN solutions – smart metering, smart monitoring, smart city and industrial IoT applications. The company is operating in Norway and Estonia, employing 25 specialists in its production and development units. NAS is the technology partner for telecom and IT infrastructure provider Levira to offer IoT services in Estonia.

Nordic Automation Systems is a member of LoRa Alliance, an open non-profit association of members who will collaborate to drive the global success of the LoRa protocol (LoRaWAN). For further information visit NAS website at www.nasys.no.